Bulbous Nocks - a Mike Loades project

Silent Thunder Ordnance

So lets start this off with a big thank you to Mike Loades for supplying images, dimensions, arrows, and ultimately the impetus for this entire project. To that end, we've been working on Mughal style bulbous nocks, but made for modern arrows and strings. Mike's stated goals for this project were to create a modern interpretation of a Mughal bulbous nock to aid in mounted archery speed shooting.

To be clear, before someone nitpicks historical inaccuracies of this project, no these nocks are not nor were meant to be perfect replicas. Furthermore, we've been modifying dimensions and tuning the design for Mike Loades' specific application, rather than aiming at the general public. As the project evolved, to achieve functionality and its ultimate ends, we've drifted further and further from the design's historical roots.

Initially the host arrow was Gold Tip Traditional 500 arrows. Our first gen, seen above, was a failure, but not for the reasons you might expect. Given a string diameter supplied by Mike, we matched the depth as a ratio to width of multiple historical examples, which I should add were surprisingly consistent. The result, equally surprisingly, was that the string angle on short bows was too extreme for the nock. Unless one were to draw the bow using the nock itself, or some sort of device to balance the string above and below, I simply can't imagine a way this type of nock could function. And this seems like it would be the case irrespective of string diameter, sure a larger diameter string would necessitate a deeper nock, but the ratios and string angle would remain the same. Perhaps the diameter of the bulb remaining constant would be sufficient? A puzzle, certainly.

The next gen offered a MUCH deeper string groove, and initial shooting tests were successful. With a thumb draw, you can really feel your index finger drawing the bulb backward onto the string. Unfortunately, upon further evaluation, we discovered these nocks too were unsuccessful. This time though, the gremlin was more insidious: nock mass. Upon impact, arrows endure a great deal of flex, whip, and off axis forces. Most nocks are thin, hollow, light, and only as long as they need to be. This improves their durability as that neck in the arrow, which is a fixed maximum diameter, has less external mass to whip around. We're now doing the opposite, building a taper and large bulb on the end. The, now-obvious-with-hindsight result? Nocks failed at the neck where they insert into the arrow with sufficient shot count.

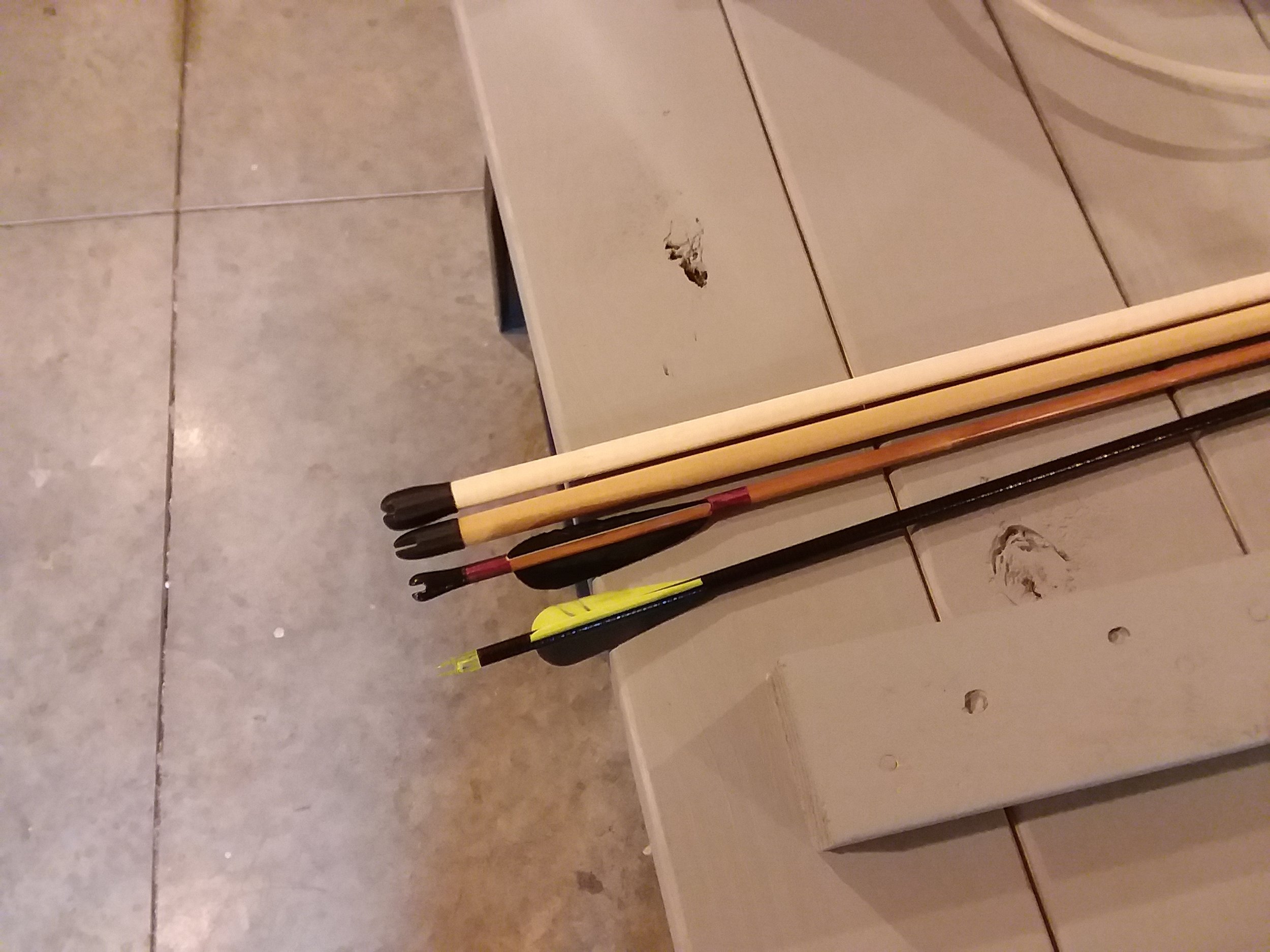

Clearly then, on carbon arrows this wasn't going to work. But what about a more reinforced design? How about nocks for the more typical 11 degree taper found on most wood and some bamboo shafts? This appears to have solved our durability problem, reduces the mass of the nock itself, and the results performed as desired. Mike was extremely pleased with the results as well, so much so he named them "the MikeL-Nock."

We were so pleased with the results on these arrows that, in a sister project, we adapted the design to fit our 1/2" in diameter Manchu arrows. As can be seen above, one of these was given quite a test when the arrow was slammed through the backstop lodging itself into the concrete wall with enough force to stick..... and be difficult to remove. Quite a testament to it's durability, granted at absolutely comical proportions.

This may not be the last we see of these either. Other nock designs for other style arrows may be in the works. ;)